How to Use HEDP Phosphonate to Achieve The Purpose of Saving Water?

The earth is covered by 70% of surface water, but freshwater resources are still rare. Water conservation is very important. First of all, we must pay attention to industrial water that consumes a large amount of water.

In industrial water, cooling water accounts for about 60% – 70%, which is the largest part. Therefore, saving cooling water is a top priority for industrial water conservation. The emergence of HEDP phosphonate and other water treatment chemicals has provided powerful support for saving cooling water.

Recycling the cooling water greatly saves water consumption.

However, as the cooling water continuously evaporates, the concentration of salt in the water increases. At the same time, the contact of cooling water with the atmosphere, the dissolved oxygen, and bacteria content increased significantly. This leads to fouling and corrosion of circulating cooling water equipment.

Bacteria and algae grow massively in the pipeline. For those reasons, the heat transfer rate of the cooling water is greatly reduced. The frequent maintenance of cooling water equipment has affected the normal production process.

For this purpose, a water treatment agent such as HEDP phosphate must be added to the cooling water.

This chemical technique, called chemical water treatment, is a chemical technique that prevents scaling and corrosion of circulating water. It includes pre-treatment, cleaning, pickling, pre-coating, conventional addition, sterilization, and other processes.

Coagulants and flocculants are also important means for primary treatment of wastewater. Coagulants and flocculants are also important means for primary treatment of wastewater. Chemical water treatment technology is currently recognized as the most widely used and most effective means of industrial water conservation at home and abroad.

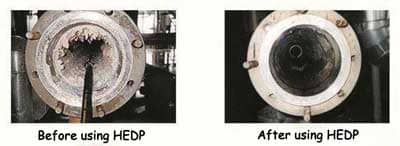

Scale and corrosion have a significant negative effect on cooling water equipment. HEDP can reduce fouling well. HEDP phosphonate provides good protection for cooling water equipment. Phosphate is an anodic corrosion inhibitor.

In the neutral and alkaline environment, the corrosion inhibition of phosphate on carbon steel depends mainly on dissolved oxygen the in water.

The reaction of dissolved oxygen with steel produces a thin layer of a γ-Fe2O3 oxide film. The growth of this oxide film takes a long time to complete. During this period, electrochemical corrosion continued to occur at the gap of the oxide film. These gaps can be blocked by continuously growing iron oxide. These gaps can be blocked by continuously growing iron oxide and insoluble iron phosphate to protect the carbon steel.

Since the HEDP phosphate reacts with calcium ions in water, the resulting calcium phosphate-prone scale has little solubility in water. Therefore, HEDP was rarely used as a cooling water inhibitor in the past.

In recent years, HEDP phosphonates have been used as cooling water corrosion inhibitors due to the development of series copolymers such as acrylic acid and hydroxypropyl acrylate. However, IRO recommends that HEDP is used together with the copolymer.

If you have any requirements for HEDP and other water treatment chemicals, you can send email to us.

![]()

Title:

How to Use HEDP Phosphonate to Achieve The Purpose of Saving Water?

Source: https://www.irohedp.com/hedp-phosphonate-save-water/