Selection and Use of Biocides in Water Treatment Chemicals

Water treatment chemicals are one of the most widely used and special products in the water industry, pollution control, and water reuse treatment projects. Water treatment chemicals include flocculants, scale inhibitors, corrosion inhibitors, and biocides.

Water treatment chemicals are used to remove suspended solids and toxic substances from water and to control fouling. Also used to reduce corrosion of water contact materials. At the same time, water treatment chemicals also have good performance in deodorization, bleaching, softening, stable water quality and desalination.

The performance of the water treatment agent largely determines the operation of the process. The final impact is water quality and cost. Therefore, it is very important to choose a good water treatment agent manufacturer.

The biocides in water treatment agents are widely used. The following is an introduction to biocides.

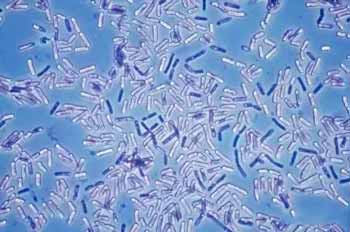

Biocides. Also known as bactericidal algaecide or slime stripper. It refers to a class of chemicals used to inhibit the growth of microorganisms such as algae in water to prevent the formation of microbial slime.

Bactericides are generally classified into two types: oxidizing bactericides and non-oxidizing bactericides. Oxidizing bactericides, such as commonly used chlorine, sodium hypochlorite, bleaching powder, etc. The effect is better in non-oxidizing fungicides. Widely used are products that can destroy the cell wall and cytoplasm of bacteria, such as quaternary ammonium salts.

Among the quaternary ammonium salts, such as dodecyl dimethyl benzyl ammonium chloride (DDBAC, 1227) slime stripping agent, etc., often have various effects such as sterilization, peeling, and corrosion inhibition. 1227 is a very promising fungicide. Now used in oil field water, industrial cooling water, etc.

Selection and Use of Fungicides

Method of delivery: continuous delivery controls the increase in the number of bacteria, as well as intermittent impact dosing. Kill large numbers of bacteria by high doses. This requires a combination of the two.

Dosing point: generally located at the far end of the sewage treatment system, such as the incoming water (before the tank). In order to ensure the water quality of the water injection, the dosing point is generally set after the filtration of the sewage treatment or the inlet of the water injection pump.

Dosing amount: continuous dosing, the starting concentration is higher, and the number of bacteria is controlled, and the relatively low doping concentration is adopted. Effective concentrations were determined by laboratory evaluation and on-site bacterial analysis. Intermittent impact dosing, regular use of higher concentrations.

The bactericide is sterilized by a sewage treatment system. Dosing cycle, dosing amount, dosing time, according to indoor evaluation and on-site bacterial analysis, adjusted by on-site practice. After adding the fungicide to the water treatment system, monitor the number of bacteria.

Sampling regularly, counting bacteria according to conventional methods, adjusting the dosing method and dosing concentration at any time to ensure the sterilization effect of the fungicide.

We produce environmentally-friendly water treatment agents for environmental protection, ensuring the stability and supply of our products. Water treatment products are widely used in steel, petrochemical, power, textile, printing and dyeing, paper and other industries. Please contact us if necessary.

Title:

Selection and Use of Biocides in Water Treatment Chemicals

Source: https://www.irohedp.com/selection-and-use-of-biocides-in-water-treatment-chemicals/